Boiler Turndown Revisited

In the June 2002 issue of Boiler Systems Engineering, we wrote an article titled “Boiler Turndown.” Contrary to conventional wisdom, the article stated that high turndown ratios are not always good — higher is not necessarily better in every case. Several boiler manufacturers incorporated the article into their training programs, and at least one major boiler manufacturer still uses it as a technical reference. There was, however, one significant point of post-publication controversy: We wrote that, in most cases, there was no significant efficiency advantage to operating a test boiler at a high (10-1) turndown ratio vs. a low (4-1) turndown ratio. We still believe that to be the case, but we recognize that the total energy capacity of a boiler — whether achieved by increased steam/water storage or a wider range of allowable operating pressures — has to be sufficient to allow the shorter cycle time associated with a lower turndown ratio. This can result in a larger boiler/footprint and, therefore, higher first cost. This obviously runs contrary to manufacturers' goals to build smaller and less costly boilers.

It also should be noted that, in our original article, we ignored so-called “shell losses” because we were considering one boiler with differing burner turndowns. If a larger boiler is chosen to provide more energy storage, convection and radiation losses — which are directly proportional to the effective surface area of the boiler shell — must be considered. These losses will, of course, adversely impact the boiler's overall efficiency, but can be addressed with insulation and surface-area design.

An alternative to a larger boiler is a shorter cycle time, which incurs an efficiency penalty because of the safety and code requirements needed for a burner purge cycle. A purge cycle must be initiated as part of each ignition sequence; because the burner is being purged with relatively cold inlet air to remove combustible-gas accumulation, heat is removed from the boiler. This reduces radiation heat-transfer efficiency and initial flame temperature. The lower flame temperature results in a decrease in flame stability. In our original article, we took into account the efficiency loss that occurs when a boiler is purged before startup.

Although efficiency and emissions were important when the original article was written, they did not have the overarching significance they do now. With the passage of the Energy Policy Act of 2005 and the increased boiler-efficiency requirements of such standards as ANSI/ASHRAE/IESNA Standard 90.1-2007, Energy Standard for Buildings Except Low-Rise Residential Buildings, energy efficiency has become a critical consideration in HVAC-equipment selection. Even more-stringent nitrogen-oxide- (NOx-) emissions standards continue to affect burner design, particularly for boilers in states such as California.

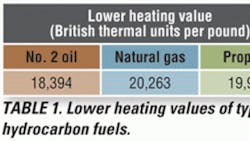

For low- and ultralow-NOx burners, regardless of turndown, fuel selection is critical. Most (or all) commercial low-NOx burners will fire a hydrogen-rich gas. Although long understood and accepted anecdotally, recent work at Turkey's Selcuk University has evidenced the directly proportional relationship between a fuel's hydrogen content and its lower heating value (LHV).1 Table 1 shows common hydrocarbon fuels and their LHVs.2

Burning No. 2 oil naturally will be more efficient than burning a natural gas simply because of the amount of hydrogen in the fuel. Water vapor has significantly more heat capacity than carbon dioxide (CO2) or nitrogen (N2). This difference can account for more than 3 percentage points of efficiency, depending on operating conditions and boiler efficiency.

Because emissions now are one of the largest issues facing fossil-fired boilers/heaters, several emission-control strategies have been developed:

- Fuel and air staging.

- Premixed combustion.

- Flue-gas recirculation.

- Water/steam injection.

- Cooling/heated-flame surfaces.

- Catalytic combustion.

- Oxygen firing.

Each of these methodologies requires some type of alteration to the combustion process and affects efficiency and combustion in a different way. Strategies for one type of fuel may not be as effective for another. For example, premixed oil combustion is difficult to achieve because the oil must be atomized/vaporized before it is mixed with oxygen for combustion. The same is true of fuel and air staging. Each fuel has different reaction rates that control the combustion and emission-formation processes, and staging the fuel for emission reduction should optimally take this into consideration.

Page 2 of 2

Ultralow-NOx burner efficiency also is inseparably linked to the technology employed to generate lower NOx formation. One of the most common ways to reduce NOx formation in gas combustion is to operate the burner with premixed combustion and higher excess air. This method allows heat from the combustion process to be distributed over the increased air volume and significantly reduces peak flame temperature. For this reason, premixed gas burners are the simplest form of ultralow-NOx technology. Some burner geometries allow stable operation over large turndown ratios and in many furnace applications. An efficiency penalty is caused by the excess air that is employed to reduce the flame temperature. With higher excess-air levels, more air (oxygen and N2) is passing through the flame, being heated to the flame temperature and exhausted out of the stack at a still relatively high exit-gas temperature. Combustion efficiency will increase with increased excess air until the excess air's heat loss is larger than the heat provided by more efficient combustion (Figure 1). The exit-gas temperature is a function of various factors, such as boiler efficiency and operating pressure, and can have a significant impact on efficiency (Table 2).

Many boiler and burner manufacturers have elected to utilize flue-gas recirculation (FGR) in place of higher excess air to achieve the same level of NOx emissions. This is a well-established design strategy that commonly is employed by manufacturers to achieve NOx emissions in the 20- to 40-ppm range. Reaching sub-10-ppm levels with this technology requires significant design considerations to support flame stability. Natural-gas flammability limits can be affected by the addition of hot surfaces and/or hot recirculated gases at the flame front because higher temperatures result in reduced lower explosive limits (LELs) and higher upper explosive limits (UELs)3. Most applications utilized to achieve ultralow-NOx combustion use more than one reduction strategy. Combinations of premixed combustion staging are incorporated with FGR to minimize the formation of NOx.

Because of the difficulty in achieving ultralow-NOx combustion, each type of burner technology must address efficiency and turndown. There is no one-size-fits-all burner design, and each burner type must be matched to the furnace geometry and boiler operating conditions. These burners can be extremely sensitive to back-pressure changes and alterations to combustion-air temperatures, making their operation very different from the old burner technologies. Additional controls often are added to burner packages to create more complex control of the combustion processes. Users must be ready to take a more involved approach to the boiler/burner operation process.

Conclusion

In our original article, we concluded that burner turndown was not a panacea for correcting low efficiency or compensating for poor equipment selection. With the current increased emphasis on energy efficiency — and emissions — we believe that is even truer now than it was then. Selecting the proper boiler and burner for any application requires careful consideration of many factors, of which turndown is just one.

References

-

Demirbas, A. (2007). Effects of moisture and hydrogen content on the heating value of fuels. Energy Sources, 27, 649-655.

-

API. (2001). API Publication 4261: Alcohols and esters: A technical assessment of their application as fuels and fuel components. Washington, DC: American Petroleum Institute.

-

Geerssen, T.M. (1988). Physical properties of natural gases. The Netherlands: NV Nederlandse Gasunie.

Did you find this article useful? Send comments and suggestions to Associate Editor Megan White at [email protected].

Larry Clark, LEED AP, is director of corporate business development for air-conditioning-contractor Hill York. Previously, he served as president, vice president of sales and marketing, and regional sales manager for MEPCO and regional sales manager for Vapor Power. An EBR boiler and mechanical lead for Consumers Energy at J.H. Campbell Generating Plant, David Thornock, PE, is responsible for the economic-based reliability of three large utility boiler systems. His previous experience includes serving as director of engineering for a commercial-boiler manufacturer, designing and manufacturing boiler and burner packages to meet customer needs and environmental regulations.