Enterprise energy-management systems (EEMS) are a hot topic, as many corporations are investigating these solutions and asking how they can be incorporated over their portfolios or within their facilities. Business owners are seeing the great benefits others are reaping from their EEMS and see themselves on the sidelines and feel they are missing out on these opportunities. Which means now is the time to be asking yourself how you should evaluate and initiate EEMS projects for your clients.

So how should you evaluate and initiate an EEMS project? What systems should you connect? What equipment should be included? Which points are the most important to evaluate and track? These are the questions many firms are discussing. These are great questions and questions which should be asked and answered before a project is developed.

In order to answer these questions, you should set up a master plan for your EEMS system’s installation. This master plan should first look into the business details of the company, its financials (superficially), and its operations to determine where EEMS can be applied and how its operational team can make use of it. This is often the step most project teams forget or forgo, as they push to do the installation in a rush to save money. Often, however, they find that their rush has caused them to miss an opportunity.

The first step is to look at three key areas of your customer’s building and how they relate to your EEMS project. Look at financial efficiency, energy efficiency, and operational efficiency and determine how your EEMS project can improve them. Then define specifics that can be focused on in the EEMS data. Each of these items (financial, energy, and operational) must be benchmarked to define specific items that can be improved to meet the goals.

Next, look at the existing systems, equipment, points, and data. Take snapshots or statistically sample each of these items and focus on which parts and pieces of these findings, if integrated, can be used to improve these operations.

Once this data is collected and evaluated, look at what pieces of data will result in the best return and match the client’s window of opportunity and investment goal. Then, determine how this data will be collected, presented, and used to create the environment to result in the proposed savings.

Many EEMS projects collect too much information or connect systems that have little opportunity for improvements or cost savings. These are the overall keys:

• Most financial systems are currently monitored well by the accounting systems. Data such as cost for energy (cost per meter, per kwh, per kw, and per square foot), and cost for operation (cost per labor hour, cost for maintenance repairs, and service contracts) should be summarized for integration or input into an EEMS tool. Linking into the accounting system may not be necessary, but a summary of financial key performance indicators may be good to send to the EEMS for integration.

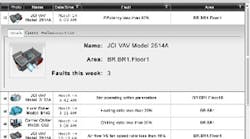

• Operations and maintenance may be more difficult, but looking at where the most money is spent or where the most inefficiency is estimated (equipment, services, and sites or duties) should be presented and tracked via dashboards to quickly focus on operational improvements. If the building has a computerized maintenance management system, there may be good summary information that can be downloaded and integrated.

• To focus on energy, investigate the utility metering. Instead of looking at submetering, start first at tracking the main metering. If management algorithms can be developed for each sites utility energy use and costs, these same reports and summaries can be produced within the EEMS.

• When picking equipment, do a quick energy analysis and find the major energy uses in the building. From this, select the system that encompass the majority of the usage and costs—equipment such as chillers, boilers, air-handling units, lighting zones, (not individual fixtures), large plug loads, and other HVAC systems. Focus the integration on “on” and “off” first, again controlling the systems and not the equipment or points.

• Keep it simple. Take baby steps. Start small, you can always add-on later.

Remember it will take time for the users to use the system and understand it. If you make it too complicated too soon, it will fail because of the users.

To summarize, your clients want to be more efficient, more competitive, grow their businesses faster, and make more profit. You know the game. Help them play it by:

1. Determining key performance indicators and developing tracking to report on these.

2. Linking real-time utility main meters to allow you to see use and daily/weekly load profiles.

3. Collect summary data from accounting and operational/maintenance systems.

4. Collect start/stop on major equipment to set standardized schedules and to be able to control the 24/7 operation.

These steps alone should result in a 10 percent to 20 percent savings in operational costs.

J. Christopher Larry PE, CXA, CEM, CEP, CIPE, LEED AP, is the Director of Energy Engineering for exp, in Richmond, VA. He has spent more than 25 years working to minimize the building industry’s energy and environmental footprint through refining building design, building modeling, performance optimization, and intelligent controls. He won “Energy Engineer of the Year in 2000 from the Association of Energy Engineers (AEE). He has held numerous positions within ASHRAE, including chairman of the Chapter Technology Transfer Committee and chairman for Technical, Energy and Governmental Activities. He is a past president of AEE and has instructed the certified energy manager training course for AEE. He is the current chairman for the Building Intelligent Quotient (BIQ) within the Continental Automated Buildings Association(CABA) and also is a member of the Zero Energy Commercial Building Consortium.