Fault Detection and Diagnostics Enters the Buildings Sector

The buildings industry has taken big steps toward better systems to monitor and control energy use in buildings in recent years, but it still is struggling to develop software that can pinpoint and diagnose a problem quickly and precisely and to provide building managers with actionable information.

"The current tools are limited in scope, hard to use, and incomplete," Michael Sohn, deputy leader of the Sustainable Energy Systems Group at Lawrence Berkeley National Laboratory (Berkeley Lab), said. “They provide little or no ability to provide feedback and diagnostics."

Sohn and his colleagues are developing methods of applying fault detection and diagnostics (FDD), a technology used routinely in industrial process control and automotive and aerospace engineering, to rapidly diagnose problems in buildings and inform human operators what needs to be fixed. Sohn's group is part of Berkeley Lab's Environmental Energy Technologies Division (EETD), but research addressing sensors and controls at Berkeley Lab is broad. Sohn's collaborators are in the Simulation Research Group, while related research on energy information systems is based in the Commercial Building Systems Group.

The FDD technology the team is developing offers many new benefits to building applications. It can provide guidance even when data are noisy or incomplete, it can identify numerous simultaneous faults, and it can operate nearly in real time to reveal those faults quickly. It functions under both steady-state and dynamic conditions, which is what the electric grid is evolving toward. Changing conditions on the grid, including the increased use of demand response to hedge power availability, and varying prices and demand resulting from highly variable weather increasingly will force building managers to adjust energy consumption in real time.

Complexity of HVAC Systems a Big Concern

HVAC systems usually are a building's most complex systems and its biggest consumers of energy. When HVAC systems are not working properly, the consequences can be expensive. According to research at Berkeley Lab, the 13 most common faults in commercial buildings in the United States cause $3.3 billion in energy waste annually.

Studies have found substantial numbers—sometimes more than 90 percent—of air-conditioning units in commercial buildings are operating with one or more faults.

Keeping HVAC systems in good repair is a full-time job for a building manager. Ensuring HVAC systems provide peak performance and comfort while minimizing energy use is only now becoming possible, thanks to the increased use of sensors and controls in the form of energy information systems (EIS) and energy management systems (EMS).

"The idea is called sensor-data fusion," Sohn said. "It's become current in the buildings industry, and it means the merging of big data with data analysis."

Accomplishing this transition requires the development of new mathematical techniques and software that can deal with building data that are less than perfect and handle the needs of building managers for quick, easy-to-understand information about the sources of problems.

Sohn, Marco Bonvini, and their colleagues have developed an algorithm that can reliably detect and estimate the magnitude of simultaneous fault conditions in buildings, in spite of messy or incomplete data.

"What's unique about this algorithm is that it works in real time—it can detect faults on the fly," Bonvini said.

The algorithm can tell building operators the probability a fault is real, the fault’s causes, the fault’s impact on energy use, and more.

"As meters pick up fouling in HVAC-system pumps, for example, the data become noisier," Sohn said. "The algorithm we developed is statistical in nature, so it incorporates the variability error that's in the measurements. Without this technique, the monitoring system could indicate too many false positives, or, what's worse, it would miss too many false negatives—real problems in the system. That would result in building managers being less trusting of the results."

A Physics-Based Approach

The FDD approach used in these tools not only is statistically robust, it is grounded in the real behavior of these systems.

"With the tools online, we can consider a physics-based approach to system optimization," Michael Wetter, deputy leader of the Simulation Research Group and a computational staff scientist for EETD, said.

The software presents various options, such as using a sequence of chillers to get a desired result, a sequence of on-off commands, or both. It allows users to consider whether pre-cooling or pre-heating a building would work. It opens up new options for managing energy use and comfort in buildings.

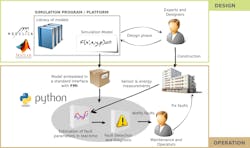

Bonvini, a postdoctoral scholar scientist in the Simulation Research Group, worked on the programming that allows the algorithm to work within an energy-management software tool chain during the design and operation phases of buildings. The software is model-based. It compares real data from building sensors to what the data should look like if the building equipment is functioning properly. The software can be used during the design phase of a building's HVAC system, with the specification data captured during design used during operation of the building.

In the model-based FDD workflow (Figure 1), a building designer uses the model library embedded within a simulation program to design a building and test its energy performance. The building is built and occupied.

"An energy information system records the performance of the building, which is available to building managers," Bonvini said. "During its operation, the same model used in the design phase can be reused by the FDD algorithm to reduce the impact of faults on energy consumption and avoid serious damage to equipment."

This software tool chain is one of the first to incorporate FDD for buildings that can be used in both the design and operational phases of buildings. It uses both the Functional Mockup Interface (FMI) Standard and the Modelica open modeling language—two standards that the international building community is using to ensure a variety of next-generation building software tools are able to communicate with each other. Berkeley Lab and RWTH Aachen, Germany, co-lead an international project, Annex 60, under the auspices of the International Energy Agency to develop open-sourced next-generation building- and energy-system software tools based on the Modelica and FMI standards.

"The connection between the algorithm and the simulation software, which could be any of several existing programs like OpenModelica or MATLAB/Simulink, is made possible by the FMI standard interface," Bonvini said. "It expands the software tool chain available to the building industry and is one of the first to combine models with real data to support building operations."

"The Modelica Buildings Library is a free, modular, open-source library of components and systems models," Wetter said. "It allows users to rapidly prototype innovative HVAC systems and, in particular, design and test the performance of actual supervisory control algorithms, which can be deployed directly to building automation systems. Modelica can also be used for the analysis of the operation of existing building systems."

Wetter leads the team developing the Modelica Library in EETD and in Annex 60.

The Modelica Buildings Library has more than 300 models and functions. Wetter's team is extending the library with another 100 models that will allow users to develop systems and controls for buildings for smart-grid integration. The team also is using the library to test how the EnergyPlus simulation engine can be improved to make it more flexible in assessing low-energy technologies and control sequences at reduced computing time.

"With these rapid prototyping capabilities, we will put building designers in a position where they can invent new HVAC configurations and new ways for controlling buildings, test them in a variety of simulation scenarios, and then use the same computer code to operate actual buildings without the cost of reprogramming control sequences in a building automation system," Wetter said.

Proving the Algorithm in the Field

Development of the algorithm is part of a three-year EETD project (now in its second year) to demonstrate and test real-time FDD in the field. Mary Ann Piette, principal investigator and head of EETD's Building Technology and Urban Systems (BTUS) Department, is leading the effort to test the FDD software. Jessica Granderson, co-principal investigator and BTUS deputy head, is overseeing the installation and development of the energy-management systems for buildings. Field tests of the algorithm are under way at a large U.S. university. The team has submitted software disclosures for two algorithms in the software package, a prerequisite to offering the software for licensing.

The team will modify and correct the algorithm and software to meet the needs of facilities managers and address any problems they find. If the initial testing is successful, they will deploy the software at many U.S. Department of Defense (DoD) buildings. The DoD, along with other agencies, is working to meet federal requirements to reduce energy intensity in their buildings by 3 percent annually through the end of fiscal year (FY) 2015 or 30 percent total by FY 2015 compared with FY 2003 baseline levels.

"What we have found is that deploying the algorithm into buildings can be the biggest challenge because it has both managerial and technical dimensions," Granderson said.

Ensuring facilities managers understand how to interpret information from the tools and that the information they are receiving is what they need will be a key outcome of the field testing and deployment.

Success will bring rewards.

"We believe that implementation of a software system with this algorithm will result in U.S. building energy savings of more than 10 percent per year," Sohn said.

This research is funded by the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy and U.S. Department of Defense's Environmental Security Technology Certification Program (ESTCP).