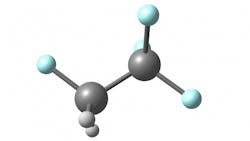

In January 2014, I (semi) humorously posted about the similarities between college football and the HVAC industry (“HVAC and … Football?”). Much of my post addressed the phaseout of hydrochlorofluorocarbon (HCFC) refrigerants. During a recent program of our local ASHRAE chapter, I was reminded just how complex of an issue this is. You’ll recall that HCFCs, which have been in use as refrigerants since the 1950s, came into widespread use when chlorofluorocarbons (CFCs), the really bad players for ozone depletion, were required by the Montreal Protocol to be phased out between 1987 and 1996. HCFCs were targeted next, but over a much longer time period (2030 to 2045 in developing countries), while the Kyoto Protocol, which entered into force in 2005 (and, incidentally, was never ratified by the United States), set reduction targets for hydrofluorocarbons, the other refrigerant type in extensive use since the elimination of CFCs.

There are several factors consumers, policy makers, and equipment manufacturers must consider when determining which refrigerants to use: cost and availability, safety, efficiency, and environmental impact—primarily, ozone-depletion potential (ODP) and global-warming potential (GWP). The effects of ODP and GWP are, of course, mitigated by the leak-tightness of the systems in which they are used and the amount of time (atmospheric half-life) they will survive in the atmosphere if/when there is leakage. HCFCs have a higher ODP than do HFCs, which have none, but HFCs often have a higher GWP. There also is the indirect environmental impact caused by the efficiency of the refrigerant. With a significant amount of our electric power still being produced from fossil fuels and a site-to-source energy-conversion factor greater than 3, the energy consumption of HVAC equipment is clearly a major contributor to greenhouse-gas emissions. So, the efficiency of equipment—determined in part by its refrigerant—is an important consideration, the cost to the user of electric energy aside.

Although it appears HFCs will be around longer than HCFCs, a great deal of pressure is being put on industry to find more environmentally friendly alternatives. And the pressure is not just on the buildings industry. Automobile air conditioning is a huge user of refrigerants; the U.S. Environmental Protection Agency (EPA) has been offering automakers Corporate Average Fuel Economy (CAFE) credits for low-GWP refrigerants other than HFC-134a since 2012. Although only a handful of vehicles, some of them lower-miles-per-gallon (MPG) models, have so far qualified using R-1234yf, those that have can add 3 to 5 MPG to their EPA label. For instance, adding 3 to 5 MPG to a 2014 Dodge Charger with 5.7-L engine represents a 17- to 28-percent improvement of (combined city and highway) fuel efficiency! Last year, the EPA also issued a proposal that could ban HFC-134a in certain other uses as soon as Jan. 1, 2016.

The importance of refrigerant selection has been recognized by the LEED and Green Globes green-building certification programs for some time. Both award points based on the volume of low-ODP and GWP refrigerants used in a building’s equipment, as well as the mitigation of leakage.

The alternatives to HFCs are complex. One example is the R-1234yf those automakers claiming CAFE credits are using. It is environmentally friendly in terms of ODP and GWP, but less efficient than HFC-134a and slightly flammable (ASHRAE 2L Flammability Class). Fortunately, the HVAC industry has been proactive on this issue, with U.S. manufacturers continuing to exhaustively test alternative refrigerants and with many of them having committed to voluntarily cut HFC emissions by 2020. According to the Air Conditioning, Heating, and Refrigeration Institute, the industry has spent nearly $2 billion on this issue since 2009 and will spend another $5 billion over the next 10 years. The good news is the research is paying off. Last year, the first commercially available chiller with HFO-1234ze(E) was introduced. This next-generation refrigerant has an efficiency close to that of HFC-134a, with zero ODP and an ultralow GWP.

In the meantime, remember that if the equipment doesn’t leak, then it doesn’t contribute to ozone depletion, regardless of the refrigerant used. So, having well-maintained, well-designed equipment is more important than ever.

About the Author

Larry Clark

A member of HPAC Engineering’s Editorial Advisory Board, Lawrence (Larry) Clark, QCxP, GGP, LEED AP+, is principal of Sustainable Performance Solutions LLC, a South Florida-based engineering firm focused on energy and sustainability consulting. He has more than two dozen published articles on HVAC- and energy-related topics to his credit and frequently lectures on green-building best practices, central-energy-plant optimization, and demand-controlled ventilation.