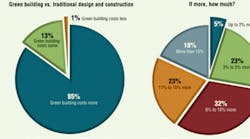

In the building-design and construction industry, “green” strategies and techniques commonly are believed to add significant cost to budgets. In fact, a Building Design+Construction magazine survey1 puts the percentage of architecture, engineering, and construction firms believing green building costs more than traditional methods of design and construction at 85, with 41 percent of those firms believing green building costs at least 11 percent more (Figure 1). A Davis Langdon study,2 however, found “no significant difference in average costs for green buildings as compared to non-green buildings,” while independent studies by the State of California3 and the U.S. General Services Administration (GSA)4 indicate cost premiums are minimal. With about 90 percent of the total cost of building ownership coming in the form of operation and maintenance—two areas in which designing for certification under the U.S. Green Building Council's (USGBC's) Leadership in Energy and Environmental Design (LEED) Green Building Rating System can save enormously—any additional costs for building green are recouped in one to two years on average, with exponential cost savings—cost savings that leave traditional construction far behind—thereafter.

This article examines available research on the cost of green buildings and explores sources of the misconception green buildings cost more than conventional buildings.

SOURCES OF MISCONCEPTION

The misconception green buildings cost more than conventional buildings stems in part from a lack of project experience. Despite approximately 50-percent annual growth in the number of projects for which LEED certification is sought, the percentage of new-construction projects registered in the United States is only about 10. What's more, many project teams pursue certification utilizing an antiquated approach to building programming and budget analysis.

“We continue to see project teams conceiving of sustainable design as a separate feature,” the authors of the Davis Langdon study2 say. “This leads to the notion that green design is something that gets added to a project—therefore, they must add cost. This tendency is especially true for less-experienced teams that are confronting higher levels of LEED certification (Gold and Platinum).”

Sustainability is a programming issue and must be addressed before budgets are established, an approach that enables project teams to apply a holistic and integrated design methodology (see sidebar “Collaboration Is Key”).

THE BUSINESS CASE FOR HIGH PERFORMANCE

By making the right decisions during the design and construction of a building, dramatic reductions in operation and maintenance costs will be realized—often, with little or no additional up-front cost.

How do we make the “right decisions”? Overwhelmingly, the biggest hurdle to overcome is convincing owners, design teams, and construction firms that achieving green-building certification does not increase costs (see sidebar “The ‘Triple Bottom Line’”). Once the green-building-increases-costs myth is busted, there is virtually no reason for LEED certification not to be pursued for a building.

Industry experts are investigating ways to determine the total environmental impact of buildings and construction. A 2005 report8 defines life-cycle assessment (LCA) as “a way to measure the environmental performance of products over their life cycle, from ‘cradle’ (where the raw materials are extracted) to ‘grave’ (where the product is disposed of). The LCA of a building will indicate how much climate change was caused by the building.” By that definition, determining the total cost of ownership of a commercial building begins at project conception and continues beyond the building's useful life. More time and collaboration is needed to fully develop standards for LCA. In the meantime, there are plenty of hard-cost reasons for owners and developers to engage in sustainable design and construction.

COST STUDIES

Following are summaries of the most widely referenced studies supporting the positions presented in this article.

“The Costs and Financial Benefits of Green Buildings,” 2003

The first comprehensive green-building cost analysis, the State of California-commissioned “The Costs and Financial Benefits of Green Buildings”3 concludes “that minimal increases in upfront costs of about 2 percent to support green design would, on average, result in life-cycle savings of 20 percent of total construction costs—more than 10 times the initial investment. For example, an initial upfront investment of up to $100,000 to incorporate green-building features into a $5 million project would result in a savings of $1 million in today's dollars over the life of the building.”

“LEED Cost Study,” 2004

In many ways, the GSA's “LEED Cost Study”4 supports the conclusion of “The Costs and Financial Benefits of Green Buildings” that sustainable building is cost-effective. As a result of the study, the GSA “requires all new-construction and major modernization projects to be certified through the LEED program, with an emphasis on obtaining Silver ratings. Individual client agencies may also work with GSA to pursue even higher levels of LEED certification. Using the results of the LEED cost study, the GSA intends to refine the amount of ‘sustainability’ funding provided for future projects. … The new budget allocation will be enough to ensure that projects can achieve LEED Certified ratings; however, project teams will be encouraged to achieve the highest level of LEED rating that is practical within the overall budget. With the revised budget allotments (which will likely vary between 2.5 percent and 4.0 percent, depending on the project), the study indicates that many Silver-rated buildings should be possible, as well as occasional Gold-rated projects.”

As shown in Table 1, “The range of estimated construction-cost impacts for the Certified- and Silver-rated scenarios falls below the 5-percent estimating accuracy that would normally be expected of early conceptual estimates,” the study says. “In addition, the construction-cost impacts for all of the rated scenarios, including Gold, fall below the 10-percent design contingency that is carried in most GSA project budgets at the concept phase. These numbers imply that in some scenarios (depending on the design solution, market conditions, and other contingency factors), a LEED rating could potentially be achieved within a standard GSA project budget (without a green-building budget allowance). By including a dedicated green-building allowance, the potential for GSA buildings to achieve higher LEED rating levels—with the attended benefits—is substantially greater.”

“The Cost of Green Revisited,” 2007

Building on a study performed by Davis Langdon in 2004, “The Cost of Green Revisited”2 found, “Many project teams are building green buildings with little or no added cost and with budgets well within the cost range of non-green buildings with similar programs.” Additionally, “In many areas of the country, the contracting community has embraced sustainable design and no longer sees sustainable-design requirements as additional burdens to be priced in their bids. … This study shows that many projects are achieving certification through pursuit of the same lower-cost strategies and that more advanced or more expensive strategies are often avoided. Most notably, few projects attempt to reach higher levels of energy reduction beyond what is required by local ordinances or beyond what can be achieved with a minimum of cost impact.”

The authors found, “The cost of documentation remains a concern for some project teams and contractors, although … as teams become accustomed to the requirements, the concern is abating somewhat.”

“Greening America's Schools: Costs and Benefits,” 2006

According to “Greening America's Schools: Costs and Benefits,”9 K-12 schools typically are designed just to meet building codes.

“Design of schools to meet minimum code performance tends to minimize initial capital costs, but delivers schools that are not designed specifically to provide comfortable, productive, and healthy work environments for students and faculty,” the study says. “Few states regulate indoor-air quality in schools or provide for minimum ventilation standards. Not surprisingly, a large number of studies have found that schools across the country are unhealthy—increasing illness and absenteeism and bringing down test scores.”

The report's review of 30 green schools nationwide “demonstrates that green schools cost less than 2 percent more than conventional schools—or about $3 per square foot—but provide financial benefits that are 20 times as large.

“Greening school design provides an extraordinarily cost-effective way to enhance student learning, reduce health and operational costs, and, ultimately, increase school quality and competitiveness,” the study concludes.

“The financial savings are about $70 per square foot, 20 times as high as the cost of going green (Table 2),” the study says. “Only a portion of these savings accrue directly to the school. Lower energy and water costs, improved teacher retention, and lowered health costs save green schools directly about $12 per square foot, about four times the additional cost of going green. For an average conventional school, building green would save enough money to pay for an additional full-time teacher. Financial savings to the broader community are significantly larger and include reduced cost of public infrastructure, lower air and water pollution, and a better-educated and compensated workforce.”

REFERENCES

-

BD+C. (2007). Green buildings research white paper. Available at http://www.loginandlearn.com/course/overview.php?courseid=647

-

Matthiessen, L.F., & Morris, P. (2007). The cost of green revisited. Available at http://www.davislangdon.com/USA/Research/ResearchFinder/2007-The-Cost-of-Green-Revisited/

-

Kats, G. (2003). The costs and financial benefits of green buildings. Available at http://www.ciwmb.ca.gov/greenbuilding/design/costbenefit/report.pdf

-

GSA. (2004). LEED cost study. Washington, DC: U.S. General Services Administration. Available at http://www.ecy.wa.gov/programs/swfa/greenbuilding/pdf/gsaleed.pdf

-

EERE. (n.d.). Net-zero energy commercial building initiative. Available at http://www1.eere.energy.gov/buildings/commercial_initiative/whole_building.html

-

AIA/AIA CC. (2007). Integrated project delivery: A guide. Washington, DC: The American Institute of Architects. Available at http://www.aia.org/contractdocs/AIAS077630

-

Mills, E., et al. (2004). The cost-effectiveness of commercial-buildings commissioning. Berkeley, CA: Lawrence Berkeley National Laboratory. Available at http://eetd.lbl.gov/Emills/PUBS/PDF/Cx-Costs-Benefits.pdf

-

BD&C. (2007). Life cycle assessment and sustainability white paper 2005. Available at http://www.bdcnetwork.com/article/CA6283728.html?industryid=42784

-

Kats, G. (2006). Greening America's schools: Costs and benefits. Washington, DC: Capital E. Available at http://www.cap-e.com/ewebeditpro/items/O59F9819.pdf

James D. Qualk, LEED AP, is a vice president of SSRCx LLC, the commissioning subsidiary of Smith Seckman Reid Inc. As leader of the firm's Sustainable Solutions Group, he manages operations and directs the marketing and sale of services that include Leadership in Energy and Environmental Design (LEED) Green Building Rating System facilitation, LEED feasibility analysis, energy modeling, and commissioning. Paul McCown, PE, CEM, LEED AP, CxA, is a consulting engineer with the Sustainable Solutions Group, providing LEED-facilitation, retrocommissioning, and energy-analysis services.

SIDEBAR: Collaboration Is Key

Traditionally, when an owner embarks on a building project, he or she hires an architect and perhaps a construction-management firm. Before “specialty consultants” are hired, the facility is programmed and design decisions are made. With such limited input, the ability to integrate design elements is diminished severely.

Particularly when sustainability is a priority and Leadership in Energy and Environmental Design certification a project goal, all stakeholders must be engaged as early in a project as possible. According to the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy (EERE), these can include “architects, engineers, building occupants and owners, and specialists in areas such as indoor-air quality, materials, and energy use.”

The path to a high-performance commercial building is a process called “whole-building design,” which the EERE defines as design that “considers all components and subsystems during the initial design phase.”5

Whole-building design “integrates all the subsystems and parts of the building to work together,” the EERE says. “Because all the pieces must fit together, it is essential that the design team be fully integrated from the beginning of the process.”

In 2007, The American Institute of Architects (AIA) introduced an approach called “integrated project delivery” (IPD).6 According to the AIA, IPD “integrates people, systems, business structures, and practices into a process that collaboratively harnesses the talents and insights of all participants to optimize project results, increase value to the owner, reduce waste, and maximize efficiency through all phases of design, fabrication, and construction.” The AIA further explains that: “IPD teams can include members well beyond the basic triad of owner, architect, and contractor. In all cases, integrated projects are uniquely distinguished by highly effective collaboration among the owner, the prime designer, and the prime constructor, commencing at early design and continuing through to project handover.”

SIDEBAR: The ‘Triple Bottom Line’

Inherent in high-performance buildings are financial prosperity for the owner, occupant satisfaction, and environmental conservation, which often are referred to as the “triple bottom line.”

Triple-bottom-line benefits are either quantitative or qualitative.

Quantitative. Quantitative benefits are objective in nature. They can be measured directly and reproduced independently across all project types and locations. Studies usually can stand on their own merit without comparison.

The most common example of a quantitative benefit is money saved through energy efficiency. Other examples include water savings, decreased maintenance, longer component/system life, lower insurance premiums, tax benefits, and reduced tipping fees.

Qualitative. Qualitative benefits are subjective in nature. They can be measured directly or deduced indirectly and must be qualified on a case-by-case basis. Studies usually must be grouped for validity to be established.

The most common example of a qualitative benefit is assurance building systems are designed and installed according to project intent. This is gained through commissioning, the scope and fee of which vary greatly by building type. For existing buildings, a 2004 study7 found median commissioning costs of 27 cents per square foot, whole-building energy savings of 15 percent, and payback times of 0.7 year; for new construction, median commissioning costs were $1 per square foot (0.6 percent of total construction costs), yielding a median payback of 4.8 years (excluding quantified non-energy impacts).

Other qualitative benefits include the ability to charge more for rent, fewer vacancies, less turnover, higher employee productivity, better retail sales, reduced hospital stays, less susceptibility to building-born illnesses, and better overall occupant health.