As a consulting engineer during the 1970s, Greg Cunniff worked closely with another engineering professional, Dan Prill, at the request of Montana Bell. The project: a new 100,000-sq-ft facility to house telephone switching equipment.

"Our first energy crisis was upon us, and the telephone giant—with all that energized gear—wanted to find ways to reduce their energy consumption," Cunniff, now application engineering manager for Taco Inc., recalled.

Cunniff and Prill won the engineering contract based in part on their offbeat plan to build in "nighttime economizer cooling." Preparations would entail doubling the thickness of the facility’s standard 6-in. concrete slab.

"The foot-thick slab would allow us to embed 6-in.-round, nonmetallic sonotube ducts through the length of the floor slabs of the multistory building," Cunniff explained. "At night, we'd pull cool mountain air into the ducts, wicking away heat, creating a thermal-storage (cooling) system. During the day, warmer air within the structure was cooled by being blown through the ducts to air-handling units and discharged through diffusers at ceiling level."

The cooled air would cascade down into the large open spaces, measurably reducing the mechanical cooling load.

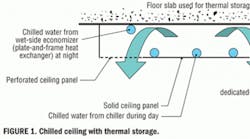

Cunniff was reminded of the Montana Bell project while attending ISH 2011 in Frankfurt, Germany. There, he saw an exhibit for a thermal-storage system coupled with radiant cooling for commercial facilities. Cold nighttime air is blown through a cooling tower. The resulting cooled water is moved through a plate-and-frame heat exchanger and circulated through cross-linked-polyethylene (PEX) tubing attached to the underside of floor slabs. During the day, warmer building air is blown through narrow plenums below the slabs. The air is cooled and discharged through perforated grilles in a radiant ceiling (Figure 1).

"The movement of cooler air formed a gentle convection within enclosed spaces, but not enough air volume for evaporative cooling," Cunniff said.

This approach has two advantages:

- Reduced energy consumption. The use of nighttime economizer thermal storage in building slabs can reduce daytime cooling energy consumption by up to 30 percent.

- Increased radiant-cooling or chilled-ceiling capacity. Chilled ceilings (Figure 2) have a fairly low cooling capacity of 20 to 30 Btuh per square foot. Passive chilled-beam systems, on the other hand, have a cooling capacity approaching 150 Btuh per square foot, while active chilled-beam systems have a cooling capacity approaching 400 Btuh per square foot.

Higher capacities are achieved by increasing the convective component of the chilled beam. This is done by increasing airflow over the chilled-beam coil, which increases heat transfer. In the case of passive chilled beams, the convection is natural (Figure 3), while in the case of active chilled beams, it is forced (Figure 4).

Blowing dedicated outdoor air over the underside of the floor slab can increase the capacity of this hybrid chilled ceiling by up to 30 percent.

Although building professionals in the United States have yet to embrace the concept of thermal-mass-linked radiant cooling, they are exploring the newest, coolest radiant technology: chilled-beam systems.

Chilled Beams

An alternative to conventional variable-air-volume (VAV) systems, chilled beams circulate chilled water through tubing embedded in a metal ceiling fixture to wick away heat. The business end of a chilled beam is made of copper tubing bonded to aluminum fins. The beam is housed in a sheet-metal enclosure typically placed at ceiling level.

There are three types of chilled beams: passive, active, and integrated/multiservice.

The difference between passive and active chilled beams, both of which are receiving significant attention in the United States, concerns airflow and the way fresh air is delivered to a space.

Integrated/multiservice chilled beams have circulation systems incorporated into lighting, sound, sprinkler, and cable pathways. They are used in Europe, but have not yet been explored in the United States.

"What makes this technology so interesting is its broad applicability for commercial structures and extreme energy and thermal efficiency," Cunniff said. "A key advantage is that a chilled-beam system requires very little ceiling space and height."

Another advantage is the high energy-carrying capacity of water via pipes. A forced-air system is significantly less efficient because of the low density of air, necessitating large ducts.

Integration of Hydronics and Forced Air

Because chilled beams are ceiling-mounted and do not use drain pans, chilled-water-supply temperature must be above the ambient dew point. As a result, dehumidification, or latent cooling, is handled by a dedicated outdoor-air system (DOAS).

With passive chilled-beam systems, outdoor air is supplied through a separate diffuser or grille in the room. With active chilled-beam systems, it is supplied through the beams.

"The amount of outside air required to operate a typical chilled-beam system is much less than that needed for a forced-air system," Cunniff said. "A chilled-beam system typically needs only one air change per hour, using outside air to pressurize the space to prevent the infiltration of outside air. With a forced-air system, that need grows to eight to 10 air changes of recirculated and fresh air to cool a space."

Also reduced—often, by 80 to 90 percent, compared with conventional all-air systems—is the amount of air circulated by the central system.

"The net result is lower energy consumption and operating costs," Cunniff said.

With active chilled-ceiling and chilled-beam systems, energy to operate fans is reduced dramatically because of the low pressure of the relatively small amount of primary air being circulated by the central system. Figure 5 shows that a radiant-cooling/chilled-beam system can reduce electrical-energy demand by almost 25 percent.

Chilled-Water Flow

In a radiant chilled-ceiling system, chilled-water temperature must be above dew point—typically, 55°F to 60°F—to prevent condensation from forming on the underside of panels. The difference in temperature between the chilled water and a 75°F room, then, is 15°F to 20°F, as opposed to the 30°F to 35°F with a conventional chilled-water system, which uses 40°F to 45°F chilled water. As a result, higher chilled-water flow rates—4.5 to 6 gpm per ton using chilled-water delta-Ts of 4°F to 5°F, as opposed to the 2 to 3 gpm per ton using delta-Ts of 8°F to 12°F with a conventional chilled-water system—are required to achieve reasonable capacities.

Even with higher flow rates, the capacity of radiant chilled panels and ceilings is relatively low, in the range of 20 to 40 Btuh per square foot. While this is within the range of cooling loads for interior spaces, it may not be adequate for interior spaces with exterior walls and windows with high solar loads.

Lowering a chilled-ceiling panel to below ceiling level and making it an open coil (Figure 3) can increase panel capacity to approximately 120 to 150 Btuh per square foot.

With passive chilled beams, ventilation air is delivered via a separate air-handling system; with active chilled beams, it is delivered via a central air-handling system.

"Ventilation air is cooled or heated to partially handle temperature-driven sensible loads, while in the summer being sufficiently cooled and dehumidified to handle all of the internal moisture-driven latent loads," Cunniff said. "With active chilled beams, air from the chilled beam is introduced into the space through a slot diffuser, creating a Coanda effect—the tendency of a fluid jet to be attracted to a nearby surface or, in this case, the ceiling."

Inducing warm room air to blow through a chilled coil substantially increases the capacity of a chilled beam. Active-chilled-beam coil capacities are in the range of 350 to 600 Btuh per square foot. Added to this is the capacity of the primary air from the DOAS. Depending on its temperature and quantity, this air can add up to 300 Btuh per square foot of capacity. An active chilled beam can deliver 500 to 900 Btuh per square foot between the chilled coil and primary air (Figure 4).

Primary/ventilation air is introduced into an active chilled beam through a series of nozzles. This induces room air into the chilled beam and, in turn, through a water coil. Induced room air is cooled and/or heated by the water coil, then mixed with ventilation air and released.

"The technology works in tandem with a central air system, which is calibrated to circulate only the amount of air needed for ventilation and latent-load purposes," Cunniff said. "The chilled beams provide the additional air movement and sensible cooling and/or heating required through the induced room air and secondary water coil."

As ventilation air moves through venturi nozzles, creating a low-pressure zone within an active beam, room air is induced upward (Figure 4), where it makes contact with the cooling coil. This air and primary ventilation air then mix and are delivered through linear slot diffusers.

"It's in this way that chilled beams transfer a huge portion of cooling or heating loads from the less-efficient air-distribution system to the greatly more efficient water-distribution system," Cunniff said. "As more systems are installed here in Canada and the U.S., it’s becoming clear that chilled-beam technology has developed into an alternative to conventional variable-air-volume systems."

This file type includes high resolution graphics and schematics when applicable.

Conclusion

The benefits of radiant-cooling/chilled-beam systems include:

- Increased comfort because radiant-cooling/chilled-beam systems circulate less air and do not create drafts or evaporative cooling on skin.

- Low noise because radiant-cooling/chilled-beam systems circulate less air than all-air systems, such as VAV systems.

- Low energy consumption because fan use is minimized. Pumping water is far more efficient than blowing air.

- Reduced floor-to-floor building height and maximization of space because chilled ceilings/chilled beams do not require large ductwork and fans.

- Lower first cost and additional space savings because only one pipe can be used in an injection mixing/pumping system to serve multiple temperature requirements.

A journalist focusing on the plumbing-and-mechanical, HVAC, geothermal, and solar- and radiant-heat industries, John Vastyan is owner of Common Ground, a trade-communications firm. He can be reached at 717-664-0535 or [email protected].

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].