In Houston and other U.S. cities, a new health-care-delivery model is emerging: Large centrally located urban hospitals are giving way to smaller community-based facilities intended to attract patients by being more accessible. ASHRAE has supported this movement through publication of “Advanced Energy Design Guide for Small Hospitals and Healthcare Facilities: 30% Energy Savings.”1 One of the guide’s recommendations to reduce operational costs and greenhouse-gas emissions is to utilize air-cooled chillers with efficiencies of at least 10.0 EER/11.5 IPLV.

The Discovery Process

Recent technology innovations, combined with advances in manufacturing practices, have resulted in considerable improvements in air-cooled-chiller performance, particularly in terms of efficiency, sound, and footprint. What has changed?

Mono-rotor screw compressor. Enhanced component tolerances, less oil in circulation, the elimination of metal-to-metal sealing surfaces, and balanced component radial forces contribute to a design maximizing compression efficiency and reducing mechanical vibration and noise, leading to improved performance and reliability.

Factory-mounted variable-frequency drives (VFDs). VFDs long have been credited with helping to reduce the cost of operating both variable-torque (dynamic) and constant-torque (positive displacement) prime movers. With a chiller, VFDs help to match required refrigeration capacity to compressor output, allowing reductions in motor speed that take advantage of accompanying reductions in motor horsepower. One advantage of the screw compressor (positive displacement) is the ability to deliver high torque (lift) at very low speeds. This results in an operational window wider than that of centrifugal chillers, the avoidance of surge, and the minimization of motor horsepower at low turndowns.

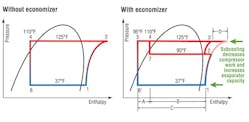

Factory-installed refrigerant economizer. Used on centrifugal chillers for many years, refrigerant economizers recently became available on some screw chillers. Through the addition of a brazed-plate heat exchanger and thermostatic expansion valve on each refrigerant circuit, refrigerant is both subcooled for additional capacity and diverted to the interstage of the compressor for increased efficiency. The increase in refrigeration capacity has led to the development of large-tonnage screw chillers with remarkably small footprints (Figure 1).

The Air-Cooled Advantage

Air-cooled screw chillers offer high performance, particularly at partial load. Their compressors typically are modulating (slide valve or VFDs), rather than stepped, which yields more accurate control. Advantages of air-cooled chillers include:

• Positive-displacement compression with no surge.

• No cooling towers.

• Avoidance of city water costs.

• Avoidance of water waste.

• Avoidance of chemical costs.

• In the event of a natural disaster, no water issues.

• No condenser pumps and piping.

• Reasonable maintenance costs.

• Saved mechanical-room space.

• Simpler control (no tower bypass) and operation (no tower freezing) in cold climates.

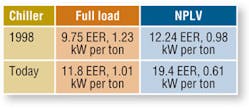

compares two air-cooled chillers: one based on 1998 efficiency levels, the other one of today’s most efficient models. Modern air-cooled chillers can perform at full-load efficiencies up to 17-percent higher and part-load efficiencies up to 37-percent higher.

Dollars and Sense

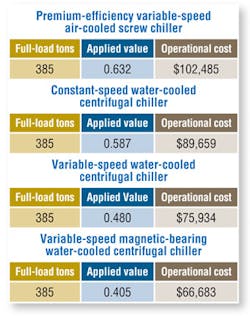

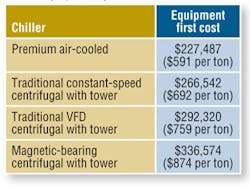

Following is a simple comparison of four chillers: one premium high-efficiency air-cooled screw chiller and three water-cooled centrifugal chillers. Both the air-cooled and water-cooled chillers were selected based on computer modeling, with the software identifying units contributing to optimal life-cycle values. These values were derived from unit efficiency and user-defined first cost, making the selected units the most attractive to own.

Each chiller required a full-load capacity of 385 tons, its performance based on standard Air-Conditioning, Heating, and Refrigeration Institute (AHRI) conditions. Kilowatt-per-ton values were calculated by software and applied to the formula 0.01A + 0.42B + 0.45C + 0.12D (typical of AHRI part-load methodology) to derive chiller-only electricity consumption. An allowance of 0.08 kW per ton (full load, 0.01A) and 0.06 kW per ton (part load, all other points) then was added to each water-cooled chiller to account for the additional cooling-tower fan and pump energy required. The tower fans and condenser pumps were assumed to run at 50-percent speed and 100-percent flow, respectively, during part-load operation. Energy cost was based on 8 cents per kilowatt-hour, typical of the utility rate structure in Houston. Table 2 illustrates the overall energy costs for each chiller. The results show how the models would perform under assigned operational conditions.

The air-cooled chiller had the highest chiller-only operational cost, while the costs associated with each water-cooled chiller dropped as efficiency improved.

The Next Step

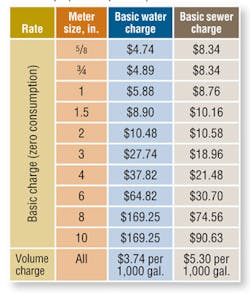

The next step was to factor in the cooling-tower water and water-treatment costs for each water-cooled chiller. Table 3 shows the most recent City of Houston commercial water rates, with volume water and sewer charges.

A comparison of water rates in Houston and other major U.S. cities proved challenging because of differences in municipal water-rate structures attributed to various peak, off-peak, service, commodity, and block consumption charges. However, one major Pacific Northwest city published rates between $4.50 and $6.03 per thousand gallons, while a large Midwestern city showed a simple rate structure of $3.50 per thousand gallons (sewer charges not included). While those cities were comparable, it is important to determine the water-rate structure specific to the location of any project.

A 2012 report2 shows users pay 75 percent more for water today than they did in 2000. The report predicts water rates will increase by 5 percent to 15 percent per year, outpaced only by heating-oil rates. City of Houston water rates are shown in Table 3, with a volume charge of $3.74 per thousand gallons for commercial users. Unless the customer is metering tower makeup water separately to account for waste, volume sewer charges (an additional $5.30 per thousand gallons) also may apply. In Houston, a separate water meter must be purchased from the utility company, a cost not included in this analysis.

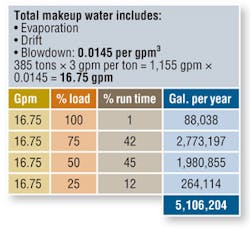

To determine cooling-tower water consumption and the resulting cost impact, a number of variables were considered: ambient wet-bulb temperature, tower loading, tower turndown, chiller/tower control strategy, type of chemical treatment used, cycles of concentration allowed, and type of tower installed. Table 4 shows estimated tower water consumption for the water-cooled chillers. Consumption was considered to be waste based on evaporation, drift, and blowdown, which are lost to the surrounding atmosphere. Using City of Houston rates, water consumption would result in a cost of $19,097 per year.

Other cost considerations are maintenance (not included in this analysis) and chemicals or water treatment. A nominal cost of $3 per thousand gallons was added for water treatment based on input from facility managers in the health system who maintain large central chilled-water plants. Note costs associated with water treatment can vary considerably based on the technology applied. When water and chemical costs are combined, the total reaches $34,409 per year. With water costs added to the chiller-only electrical costs for each water-cooled chiller, a more realistic evaluation can be made. Table 5 ranks each chiller based on total annual operating cost, including electricity and water.

Total Value

Some purchasing decisions are based solely on energy savings, while others are based solely on first cost. So that a value-based purchase can be made, both first cost and operating cost need to be considered.

shows the first cost of each chiller system. The costs are for equipment only and include contractor mark-up. The cost of each water-cooled chiller includes a cooling tower, which is required. Tower pricing includes a condenser pump, condenser piping, water-treatment equipment, and controls. The towers were valued at $92,400 ($240 per ton) each. The costs of additional refrigerant monitoring and mechanical-room ventilation are not included.

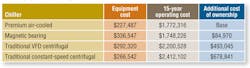

Life-cycle cost (LCC) is the total cost of owning equipment over its service life. It includes purchase, operation (including energy), maintenance, and disposal costs.4 A true LCC study is beyond the scope of this article. Likewise, the financial impacts of installation labor and materials, disposal, taxes, and saved mechanical-room space are not included.

A life-cycle study period need not be identical to the service life of equipment; in this case, a 15-year time frame was deemed suitable. (It is this author’s view that emerging technology may render major HVAC equipment obsolete long before its normal service life is over.) Resulting life-cycle operational costs include a 2-percent-per-year escalation for utility rates.

Table 7 shows first and operational costs for each chiller. As can be seen, the premium air-cooled chiller offers the lowest combination. Had the water-cooled units been judged based on chiller-only energy cost alone (water not included and first cost ignored), each may have been considered superior to the air-cooled unit in terms of overall value to the owner.

Conclusion

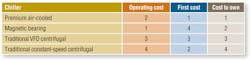

While this study of overall life-cycle operation is by no means exhaustive, it provides insight into the benefits of air-cooled chillers. Table 8 ranks each chiller in terms of operational cost, first cost, and cost of ownership.

References

1) ASHRAE. (2009). Advanced energy design guide for small hospitals and healthcare facilities: 30% energy savings. Atlanta: ASHRAE.

2) McCoy, K. (2012, September 29). USA today analysis: Water costs gush higher. USA Today. Retrieved from http://www.usatoday.com/story/money/business/2012/09/27/rising-water-rates/1595651/

3) Stanford, H.W. (2011). HVAC water chillers and cooling towers: Fundamentals, application, and operation (2nd ed.). Boca Raton, FL: CRC Press.

4) Capehart, B.L., Turner, W.C., & Kennedy, W.J. (2011). Guide to energy management (7th ed.). Lilburn, GA: Fairmont Press.

The director of health-care accounts for HTS Texas, a full-service HVACR-equipment solutions provider, David Schurk, DES, CEM, LEED AP, CDSM, SFP, has more than 30 years of HVAC-systems-based energy-efficiency experience. He can be reached at 920-530-7677 or [email protected].

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].